Green Metal Fabrication: The Shift towards Sustainability

Metal fabrication has long been synonymous with heightened energy usage, material wastage, and emissions from factories. However, with growing businesses in Toronto embracing more stringent environmental regulation and consumer pressure for sustainability, the sector is in the midst of change.

Factory facilities are embracing green technology, efficient processes, and green materials to reduce their carbon footprint. But how is it happening? Let’s examine the top ways Toronto’s metal fabrication sector is getting greener.

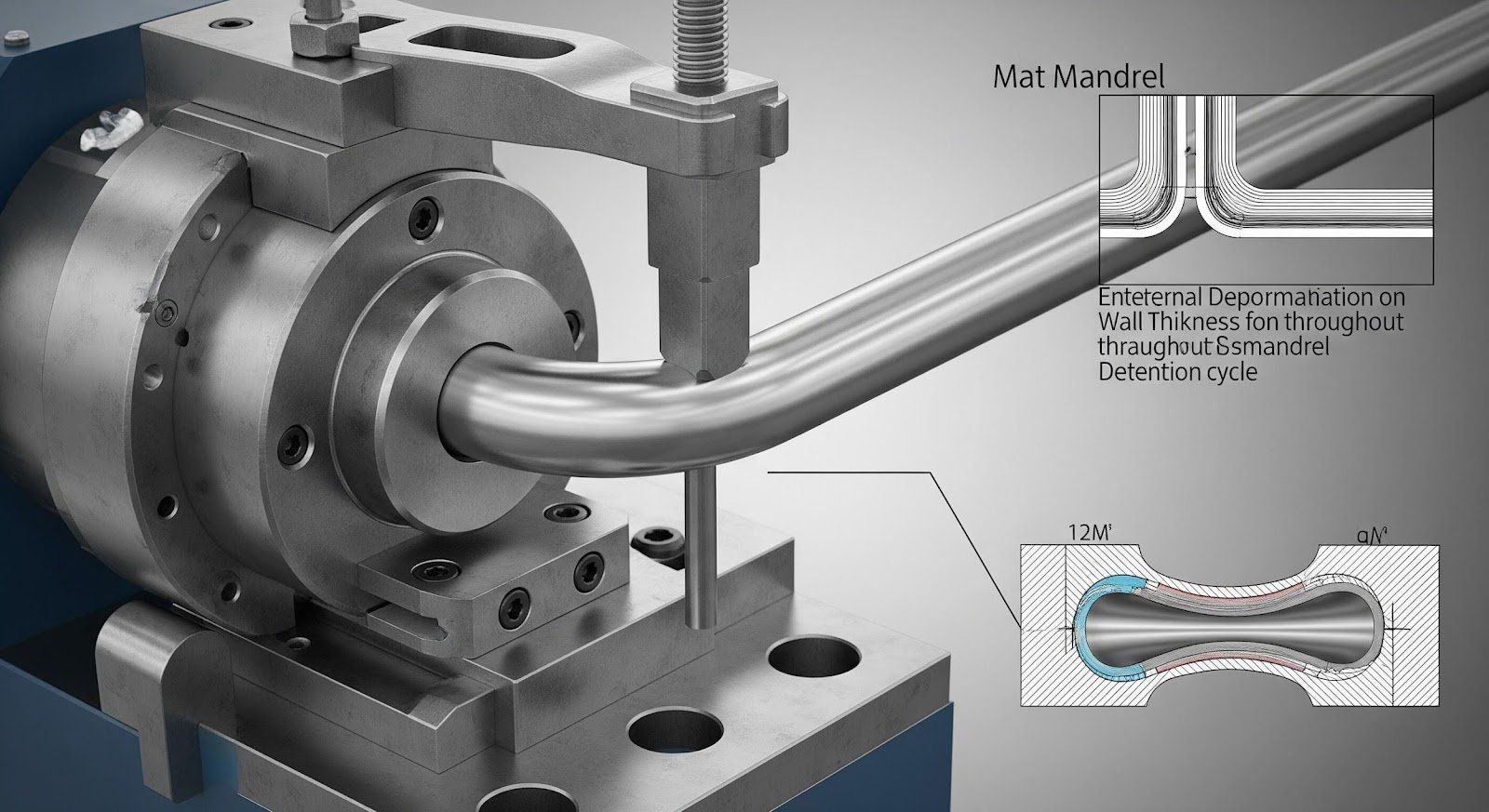

Improved Cutting Techniques: Reduced Waste, Increased Efficiency

What’s Changing?

Traditional cutting techniques wasted enormous quantities of material. Nowadays, new cutting technologies such as laser cutting and water jet cutting are extracting the maximum out of the material.

How It Benefits the Environment

- Laser cutting minimizes waste of redundant material with precise, high-speed cuts

- Water jet cutting removes the need to use toxic chemicals and heat-emission

- Computer nesting software allows for greater utilization of sheet metal, reducing scrap metal waste

All these technologies means less metals ending up in landfills and more raw material being utilized.

Metal’s Second Life: Recycling and Reusing

What’s Changing?

Toronto metal fabrication companies are stepping into the circular economy by recycling excess material and metal scrap recycling.

How It Benefits the Environment

- Scrap metal created is recycled by remelting, less then require to purchase raw materials

- Material from one past project that was not utilized is utilized in a new one, it’s reducing waste

- Requirement for mining decreased through recycling, which assists in safeguarding natural resources

By reducing recycling, metal fabrication facilities are saving money along with reducing their carbon footprint.

Energy-Efficient Equipment: More with Less Energy

What’s Changing?

Fabrication techniques such as welding, cutting, and forming consume a lot of energy. In response, many Toronto factories are bringing in energy-efficient equipment and automation.

How It Benefits the Environment

- New CNC machines save energy with high-speed precision

- Energy-efficient welding systems end wasteful power consumption with intelligent sensors

- LED lighting and smart grids assist in reducing total shop energy use

Use of energy-efficient equipment saves business money and lowers carbon footprint.

Green Coatings and Treatments: Greener for the World

What’s New?

Metal finishing has been employing dangerous chemicals to treat processes such as plating and painting for decades. Nowadays, numerous shops are embracing the eco-friendly option.

How It Benefits the Environment

- Waterborne coatings and powder paint minimize hazardous volatile organic compounds (VOCs)

- Non-toxic plating chemicals minimize toxic run-off waste

- Energy-efficient UV-curing finishes are lower-energy than conventional heat-drying

These technologies sanitize the work area and minimize pollution.

Sustainable Supply Chains: Sustainable Sourcing

What’s Changing?

Toronto metal fabricators are more often thinking about where their raw materials come from and selecting environment-friendly suppliers when they can.

How It Benefits the Environment

- Environmentally responsible metals minimize dependence on unsustainable mining operations that ruin the environment

- Material sourced locally minimizes carbon footprint from transportation

- Electronic monitoring of supply chains guarantees accountability in buying and sustainability strategies

Green suppliers assist manufacturing facilities in achieving worldwide environmental objectives.

Smart Manufacturing: AI and Data for a Greener Industry

What’s Changing?

Artificial intelligence (AI) and data analysis in real-time are increasingly assisting in minimizing waste and maximizing efficiency in metal fabrication.

How It Benefits the Environment

- Computer-aided design with AI optimizes the use of material, minimizing wastage of scrap

- Factory shops can track energy consumption in real-time, and hence they are able to find and fix inefficiencies

- Predictive maintenance prevents premature machinery replacement and extends the lifespan of machines by years

Using AI and intelligent data, factory shops are able to make greener choices.

Water Conservation: Minimizing Industrial Water Waste

What’s New?

Some of the production processes for metal utilize water to cool, clean, and cut. Additional methods are being developed by companies in order to lower and recycle the use of water.

How It Helps the Environment

- Closed-loop water systems reuse water rather than throw it away

- Filtration technology cleans contaminants so water recycling is an option

- Cutting tool nozzles saving water decrease consumption overall

Through proper management of water resources, metal production factories lower the environment’s footprint.

The Future of Green Metal Manufacturing in Toronto

Sustainability of metal fabrication is no longer a choice. It is today’s future wave. The fabrication shops in Toronto are embracing newer approaches and technologies that minimize waste, emissions, and maximize energy efficiency to a large extent.

With growing demand for green manufacturing, companies turning green will not only be assisting the world but also staying ahead. The transition to green manufacturing is revolutionizing the industry in a manner that metal fabrication shops will keep evolving to assist companies as well as the world.