When it comes to converting concepts into completed products, laser cutting has become a first-choice tool for Canadian companies. From your startup company running your initial prototype to your veteran producer running big-volume runs, laser cutting provides flexibility, accuracy, and responsiveness few processes can offer.

In this guide, we’ll explore how laser cutting supports businesses throughout every stage — from prototypes to full production — and why it’s a smart choice across industries in Canada.

Why Laser Cutting Works for Prototypes

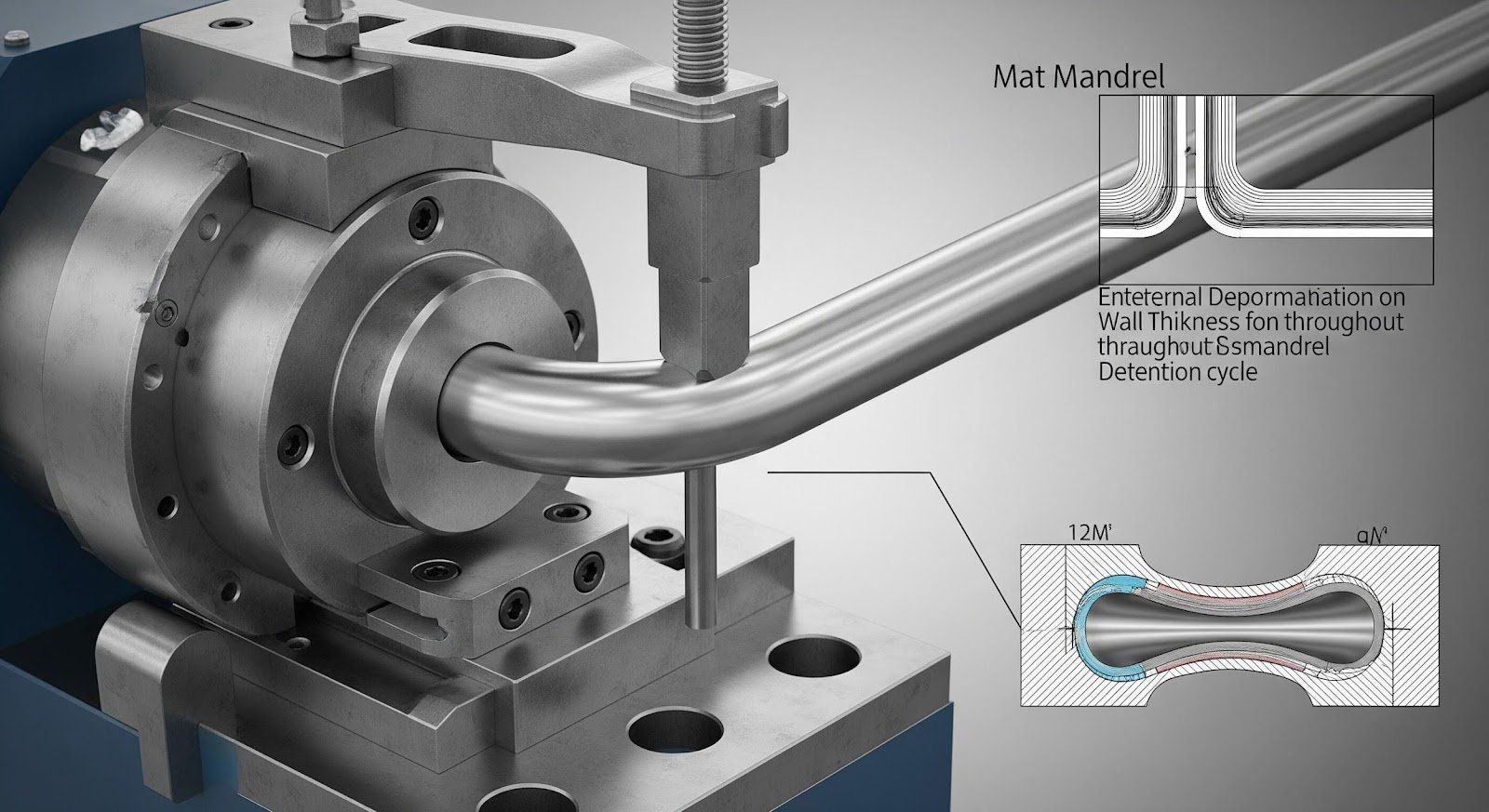

Prototyping is quick experimenting with ideas and fixing mistakes without having to spend a fortune. Laser cutting is perfect for that since it has the capability to cut parts fast with high precision and smooth edges. In that way, engineers and designers will be able to know precisely what their parts will look like and how they will fit without spending a lot of money on molds or tools.

Laser cutting removes the requirement for new tooling with each design modification. Simply change the digital file and have the machine cut the new piece right away. This reduces development cost and time for companies.

For Canadian start-ups and small firms, it can be a game-changer, allowing them to react fast and incrementally, experiment with their designs, and reach the market sooner — all without huge front-end expenses.

Smooth Transition into Small Batch Production

Following approval of a prototype, companies will usually transition into small batch production to test the market or make initial orders. Laser cutting is also especially well-suited for these types of applications, since it is able to cut complex shapes and run small lots without compromising on precision.

Traditional manufacturing techniques do involve the use of special molds or special tools, which are expensive and time-consuming to create. Laser cutting eliminates all that. It’s computer-controlled, so the same part can be reproduced identical to every other or slightly different if that’s the case.

It’s ideal for Canadian companies working with specialty markets or that need to provide customized products. It eliminates waste as well because parts are cut exactly as they are designed.

Scaling Up to Huge Production Runs

When production time comes around, laser cutting is still an excellent option — particularly for metals such as stainless steel, aluminum, and carbon steel. New laser cutting machines are fast, precise, and will operate continually with minimal downtime.

Now, most Canadian plants put money into automated equipment that adds on material, machine components, and cuts out finished parts without ongoing human intervention. It saves money and cuts shipping times.

Precision laser cutting also translates to fewer rejects and less rework. That equals improved quality and less scrap, enabling businesses to develop solid customer relationships.

Industries That Are Profiting from Laser Cutting

Laser cutting has applications in all sectors of Canadian industry. Following are some examples:

- Automotive: Brackets, parts, and specialty parts

- Construction: Frames, metal panels, and decorations

- Medical: Highly accurate parts for devices and equipment

- Electronics: Heat sinks, connectors, and cases

- Retail and Signage: Displays, logos, and specialty signs

- Agriculture: Protective covers and machine parts

In each industry, the need for precision and versatility makes laser cutting an intelligent option for production.

The Benefits for Canadian Businesses

Why is laser cutting so widely used in Canada? Here are a few reasons why:

- Accuracy: Tidy, precise cuts, with tight tolerances

- Efficiency: Rapid setup and rapid cutting cut turnaround times

- Flexibility: Cuts a very broad range of metals and thicknesses

- Economical: Low tool cost and little waste save dollars

- Variability: Easy to change design and make versions

- Domestic Support: There are a number of laser cutting companies right in the vicinity at home in Canada, offering prompt service and guaranteed delivery

Cooperating with Local Laser Cutting Experts

Working with a local laser cutting company is a major advantage. Canadian companies prefer suppliers who are aware of local regulations, supply chain requirements, and industry requirements.

In Seaborn Manufacturing, for instance, we support customers from prototype to production. Communication, quality, and on-time delivery are all critical to meeting deadlines.

Having a good local partner also results in quicker turnaround and easier collaboration. Changes or questions required? You won’t have to wait days or weeks to get the information.

How to Get Started

Considering laser cutting for your next project? Give these a try to get you started:

- Prep your design files: CAD files in DXF or DWG format should be accepted by most laser cutters. Ensure your designs are readable and error-free.

- Select the optimal material: Think of strength, weight, and finish. Ask your laser cutting supplier for guidance.

- Request a quote: Obtain a quote from several providers to compare lead time and price.

- Keep it small: Test fit and finish using prototypes or small quantities.

- Scaling plan: If growth is anticipated, design for easily scaling into larger production runs.

Final Thoughts

Prototype to one thousand units, laser cutting presents Canadian companies with a flexible, accurate, and economical production option. It enables inventors to bring their concepts into product form and manufacturers to ship quality products on time.

By choosing a laser cutting service near me, companies can move quickly, adapt designs easily, and keep quality high—all while managing costs. Whether you’re just starting out or scaling up, laser cutting is a valuable tool that fits right into the fast-paced world of modern business.